SPECIAL OPERATION FEATURES

•

Foam concentrate is supplied by positive displacement foam pump(s)

•

A diaphragm type balancing valve automatically adjusts the quantity of foam liquid entering the ratio controllers and metering device to insure an accurate foam solution

•

Any NFPA/FM approved foam concentrate can be used

•

System can use either potable or sea water

•

Foam liquid concentrate tank is made of polyethylene or stainless steel and continuously supplies foam concentrate to the foam pump

•

After depletion of the foam tank, supplementary foam liquid can be supplied during operation to meet the requirements of a large scale fire

•

System requires very low annual maintenance and operational cost with easy trouble shooting and test procedures

WATER AND FOAM PIPING

•

Schedule 40 water piping welded to ASME-IV standards

•

Foam piping SMLS stainless steel Type #316L Schedule 40 welded to ASME-IV standards

•

Flanged joints are bolted together using ASTM A-193 B7 Grade stainless steel stud bolts. Various types of gasket materials are available based upon project specs including Neoprene, Spiral worn SS or PTFE.

•

Control valves available in gate, outside stem and yoke (OS&Y) or quarter turn ball types

•

Valves available in bronze, stainless steel or steel construction

•

Brass or stainless steel check valves

•

Hydrostatic tested to 20 Bar (300PSI). The skids are designed for minimum 12 Bar (175 PSI) working pressure. Higher pressure ratings can be provided upon request.

•

Standard external paint coating

•

Optional internal and external coating with Fusion Bond Epoxy

SPECIAL OPERATION FEATURES

•

Foam concentrate is supplied by positive displacement foam pump(s)

•

A diaphragm type balancing valve automatically adjusts the quantity of foam liquid entering the ratio controllers and metering device to insure an accurate foam solution

•

Any NFPA/FM approved foam concentrate can be used

•

System can use either potable or sea water

•

Foam liquid concentrate tank is made of polyethylene or stainless steel and continuously supplies foam concentrate to the foam pump

•

After depletion of the foam tank, supplementary foam liquid can be supplied during operation to meet the requirements of a large scale fire

•

System requires very low annual maintenance and operational cost with easy trouble shooting and test procedures

SKID FRAME

•

Welded steel sub-frame

•

Custom fabricated in various dimensions

•

Galvanized for corrosion protection

•

Bolted modular assemblies for foam tank, foam pumps and piping

•

Lifting lugs provide

FOAM TRANSFER PUMP

•

Positive displacement foam pumps from Trident, Edwards and Albany rated at 110, 220, 330, 550, 1,100 L/min (30, 60, 90, 150, 300 GPM) with bronze or stainless steel construction

•

Driven by electric motor or diesel engine

•

Adjustable relief valve

FOAM TANK REFILL PUMP

•

Electrically driven, positive displacement refill foam pumps from Edwards or Albany are available in capacities from 30 to 110 L/min (8 to 30 GPM)

RATIO CONTROLLER AND METERING ORIFICE

•

Available in multiple sizes for each discharge

•

Bronze construction – controls the foam injection percentage in the water line with respective of the amount of the water flowing in each discharge

•

Foam percentage (%) pre-selected metering orifice

DIAPHRAGM BALANCING VALVE

•

Bronze construction, available in various sizes

•

Engineered to foam skid performance

FOAM CONCENTRATE CONTROL VALVE

•

A foam concentrate control valve is used in foam proportioning systems where automatic foam concentrate discharge is required.

•

Operation of the valve to the open position shall occur when water pressure is applied to the actuator inlet port. This valve can operate with pressures as low as 30 PSI or as high as 250 PSI. The valve assembly has “Open” and “Closed” position indicators. The valve shall remain in the open position until manually reset.

•

A clear water sensing line is connected from the inlet side of a ratio controller – once water starts to flow the valve will open immediately allowing the foam concentrate to be directed to the ratio controller

Foam Control Valve

Diaphragm Balancing Valve

Ratio Controller

Foam Transfer Pump

ELECTRONIC CONTROL PANEL

•

Foam pumps are controlled through electronic control panels that are UL and FM Listed and built to NFPA standards

•

Panels from Joslyn Clarke, Cutler Hammer and Metron

•

Receives signals from the water pressure switch to automatically start foam pump(s)

•

Different enclosure ratings of NEMA 4X, in stainless steel or painted type or any other configuration based upon the specifications are available

•

Pump controller main display will show the current system pressure, time and date, voltage and amp reading for all three phases

•

Manual override controls available

•

Low tank level interlock to shut off the foam pump and prevent dry running

•

Hour meter and safety shut-down alarm

INSTALLATION – TESTING – CERTIFICATION – TRAINING

•

All piping and components are individually shop hydro and flow tested after assembly for any potential leaks.

•

All valves and controls are functionally tested. Electrically driven pumps, controls, and foam system piping are tested by Chief Fire engineers

•

Installation coordination and on-site training available

DELUGE VALVES

•

Deluge valve consists of a hydro main valve, auxiliary pilot valve and three-way solenoid valve which opens or closes the main valve. Pilot control valve alternately applies pressure to relieve the pressure from within the diaphragm chamber to the main valve

•

Size: 65mm to 200mm (2.5" to 8") Class 150 flanges or grooved. Valves by ClaVal or Viking

•

Quick response to remote control

•

Fully supported frictionless diaphragm

•

Opens wide for minimum flow resistance

•

Manual override

•

Solenoid valve is used where on-off control is located

AVAILABLE OPTIONS

•

UL and FM: Third party listed components available

•

Explosion-Proof Equipment: Motors, electronic controllers, switches and other devices can be engineered for

each application or specific hazards

•

Interconnection Piping: Beyond the foam skid Chief Fire can supply water inlet or discharge piping and control valves

•

Protection Zones: Chief Fire foam skids can be supplied with multiple protection zones depending on available water source and water main sizes

•

Environment and Sun Shade: Steel structural enclosure and sun shade available to protect components

•

Sea Water Applications: All stainless steel piping, enclosures and salt-spray testing can be provided for off-shore applications

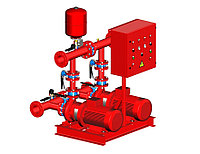

Модульный пенная насосная пожарная станция

Код: CHfoamskid Самовывоз

Самовывоз курьером

курьером Транспортная компания

Транспортная компания

Безналичный расчет

Безналичный расчет Наличными

Наличными